Silicon Bonding is attaching silicon, a synthetic rubber-like substance, to a metal component. Silicon is renowned for being flexible, strong, and heat resistant. When heated, it can be easily molded into any shape, making it a superior sealant material once dry. Silicon creates an airtight connection when combined with stainless steel or aluminum; as a result, it is less susceptible to corrosion. Additionally, silicon is an inert substance that won’t react chemically or physically with other liquids, solids, or gas. Read More…

RD Rubber Technology is an ISO 9001:2015 certified company that is highly responsive and flexible to customer needs. We can take care of design, development, and prototyping as well as short run, long run, and high volume production. We offer compression, transfer, LIM, and rubber to metal bonding. We also do silicone to thermal plastic bonding.

Since 1984 we have been providing excellent high performance solution to our client’s toughest bonded metal to rubber issues. Our skilled teams of engineers and technicians will work closely with you in order to ensure that we are filling your exact requirements on the products that we provide. Allow us to show you the difference when you work with true experienced professionals. Visit our...

For over 25 years, GSH has provided top quality contract manufacturing services, and we strive to remain on the cutting edge of our industry.

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

From molding products made of homogeneous rubber, to rubber bonded to metal as well as other various materials. Mason Rubber makes efficient use of state of the art technology to produce a quality product.

Our economical products are made from high-quality solutions that will last you for many years to come. We are a dependable manufacturer that will work with you every step of the way.

Since 1955, Jet Rubber Company, an Employee Owned Company, has been custom molding rubber and rubber-to-metal components for a variety of industries and applications.

More Silicon Bonding Manufacturers

Surface Preparation

For a surface to be prepared for silicon bonding, it should be cleaned with isopropanol to eliminate processing lubricants and create a uniform bonding surface. Other cleaners, like meth or white spirits, can leave a residue or an abrasive texture. Before bonding, always verify that all solvent has completely evaporated.

Adhesive Selection

There are few industrial adhesives used for bonding to silicone. Silicone-based adhesives frequently adhere to silicone well, but the options are restricted if one wants a quick cure that avoids isocyanate chemicals. Before applying a topcoat, a base coat called primer is applied to condition the surface. The silicone surface can be primed with a polyolefin primer.

Types of Adhesives Used for Silicon Bonding

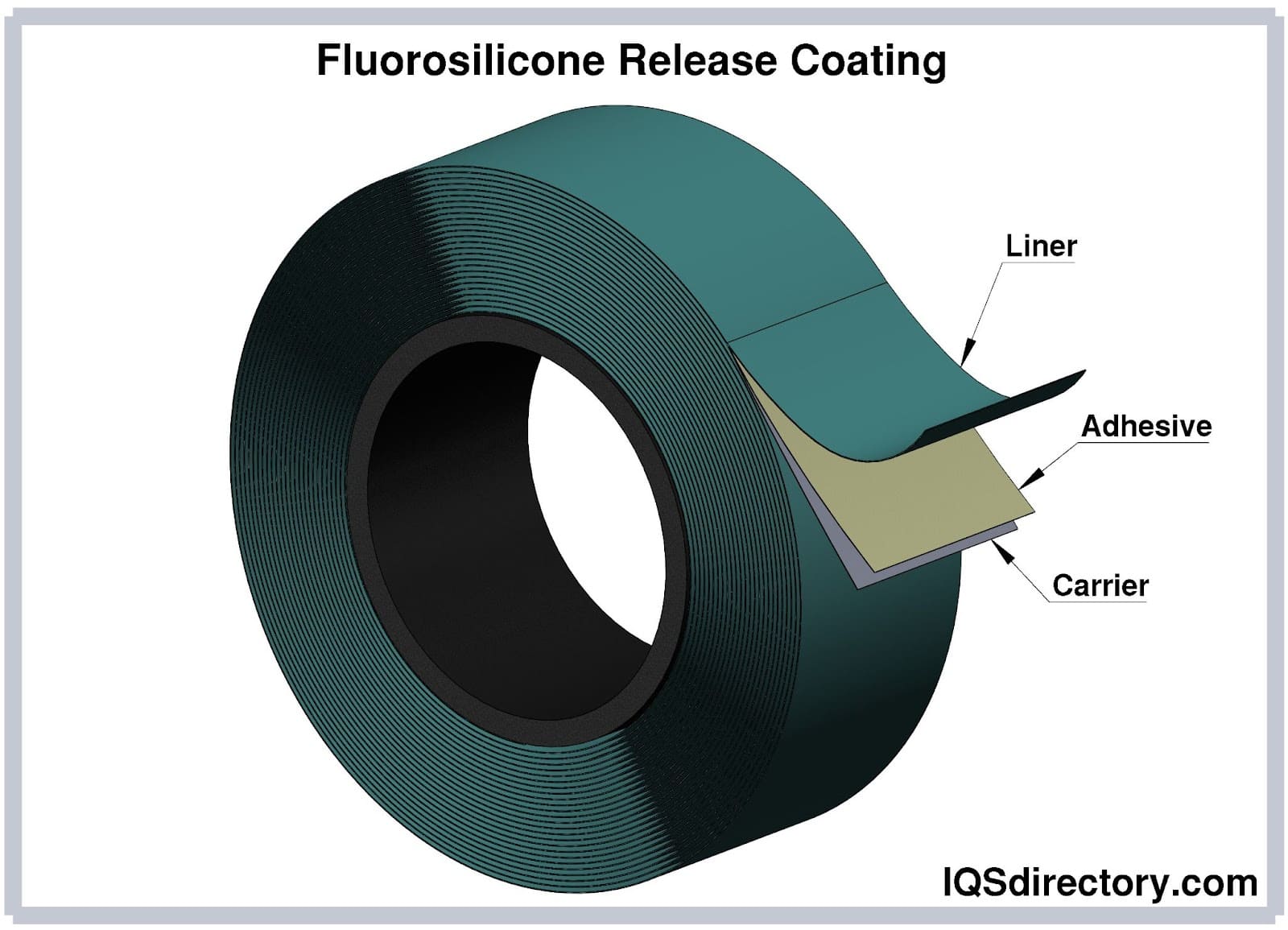

Fluorosilicone Adhesive

Trifluoropropyl, an ingredient in fluorosilicone adhesive, boosts its chemical resistance beyond that of silicone adhesives against solvents, fuels, oils, acids, and alkalis. As a result, it bonds nicely with any substrate and has great mechanical qualities. There are one- or two-part variants available. The two varieties of fluorosilicone cure are akin to silicone adhesives, wherein one variety cures when exposed to air while another requires mixing.

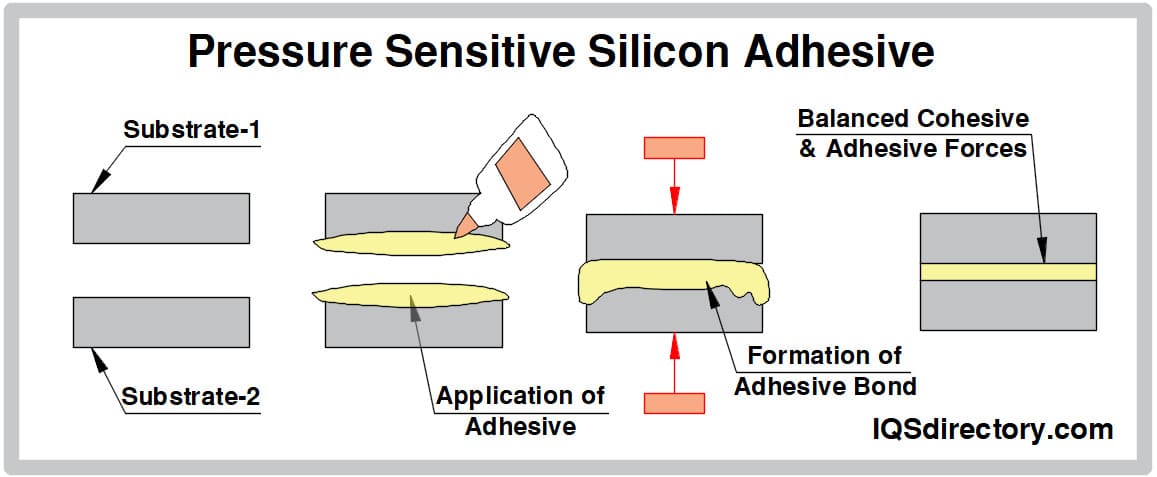

Pressure-Sensitive Silicone Adhesives

Synthetic elastomers used to create pressure-sensitive silicone adhesives are heat- and temperature-resistant and stick to low-energy surfaces. They are fastened to a substance that bonds to a surface when pressure is applied, such as plastic, fabric, paper, or metal. PSAs are composed of repetitive chains of smaller molecules joined to polymer chains of larger molecules.

Thanks to their special features, it is feasible to design and formulate PSAs to serve various functions, such as masking tape, screen liner protection film, and simple-to-install electrical insulation. They are robust to exposure to extreme climatic changes and settings and are available in several packing solutions. In addition, PSAs adhere well to low-energy substrates and difficult-to-wet surfaces.

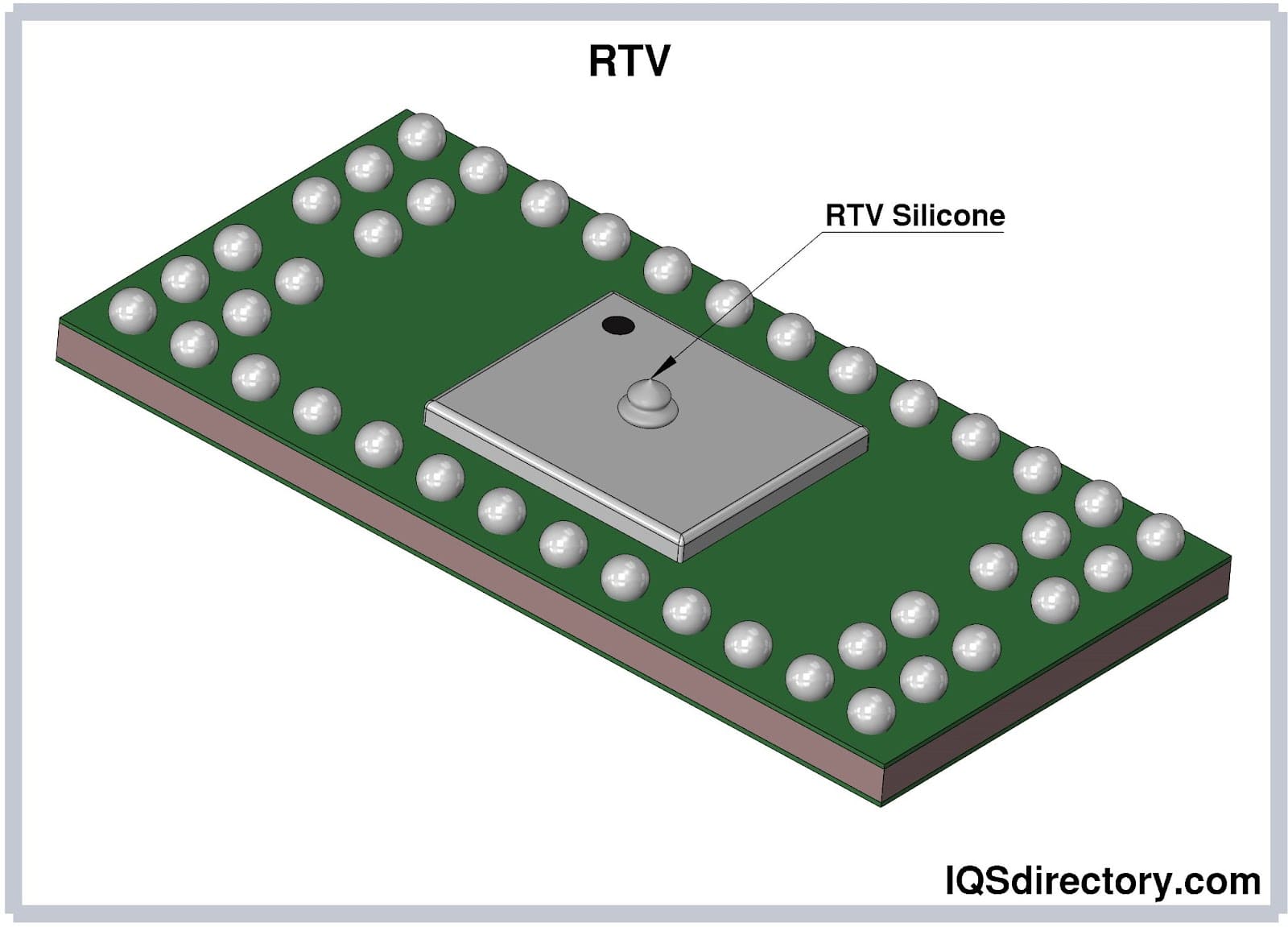

Room Temperature Vulcanizing Silicone Adhesive (RTV)

RTV silicone is a moderate adhesive that, when used to bond two surfaces, forms a gasket-like adhesive and acquires a soft texture. This adhesive's strong temperature tolerance makes it ideal for silicon bonding even when used with metals or other materials that must be used in locations with greater temperatures. Also, its strong resistance to deterioration and chemicals is frequently employed as electrical insulation. However, unlike other silicone adhesives that require more than 24 hours to cure, RTV silicone starts hardening as soon as it is exposed to air. This is why it is kept in an airtight container for storage.

Silicone Rubber Adhesive

All of the typical characteristics of silicone adhesives are present in silicone rubber adhesive. Due to its watertight qualities, it is frequently employed in marine applications as a way to seal and waterproof boats. In addition, the adhesive made of silicone rubber does not decay or crack with time.

Applications and Benefits of Silicon Bonding

- Silicon is a rubber bound to a metal frequently used in hospitals, operating rooms, and doctor's offices.

- They make great medical equipment handles, especially for surgery tools. When two materials are bonded together, there is no chance of contamination at the point where the silicon and metal meet. This is because nothing can get through the fissures.

- Silicon can withstand repeated autoclave sterilization cycles, which are required for all reusable medical equipment due to their exceptional heat resistance.

- Additionally, silicon-bonded metal is employed in blood analysis and medical equipment.

- Due to its flexibility and capacity to be compressed between two surfaces, silicone has many purposes and is frequently employed in seals or gaskets.

- Other applications include prosthetics, surgical implants, flexible medical devices, tubing, and special effects in the film industry.

- Silicone is becoming more popular for kitchen items like non-stick bakeware and molds due to its great temperature resistance.

Choosing the Proper Silicon Bonding Company

To make sure you have the most beneficial outcome when selecting a Silicon bonding company, it is important to compare at least 4 to 5 companies using our silicon bonding directory. Each silicon bonding company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each silicon bonding company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple silicon bonding companies with the same quote.

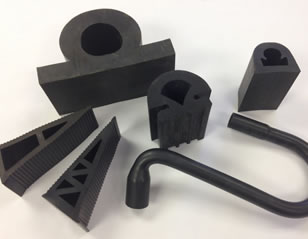

Rubber Extrusions

Rubber Extrusions Rubber Molding

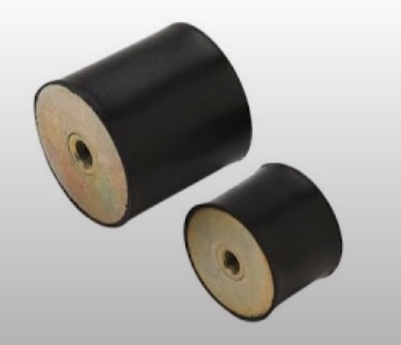

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

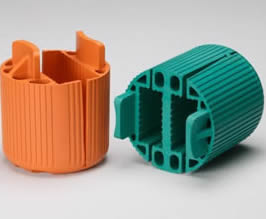

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services