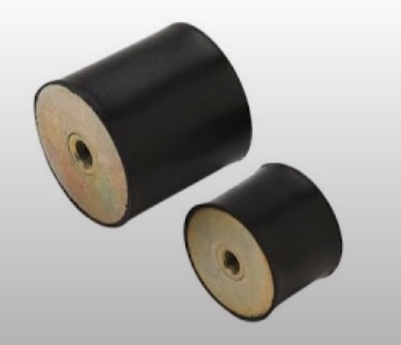

By bonding the two materials together, the benefits of each material are combined in one product that is able to withstand shock while maintaining strength and rigidity. When rubber is bonded to metal, there are three essential elements: rubber, a bonding agent and the metal substrate. The rubber may be any kind of rubber, either natural rubber or a synthetic. Read More…

RD Rubber Technology is an ISO 9001:2015 certified company that is highly responsive and flexible to customer needs. We can take care of design, development, and prototyping as well as short run, long run, and high volume production. We offer compression, transfer, LIM, and rubber to metal bonding. We also do silicone to thermal plastic bonding.

Since 1984 we have been providing excellent high performance solution to our client’s toughest bonded metal to rubber issues. Our skilled teams of engineers and technicians will work closely with you in order to ensure that we are filling your exact requirements on the products that we provide. Allow us to show you the difference when you work with true experienced professionals. Visit our...

For over 25 years, GSH has provided top quality contract manufacturing services, and we strive to remain on the cutting edge of our industry.

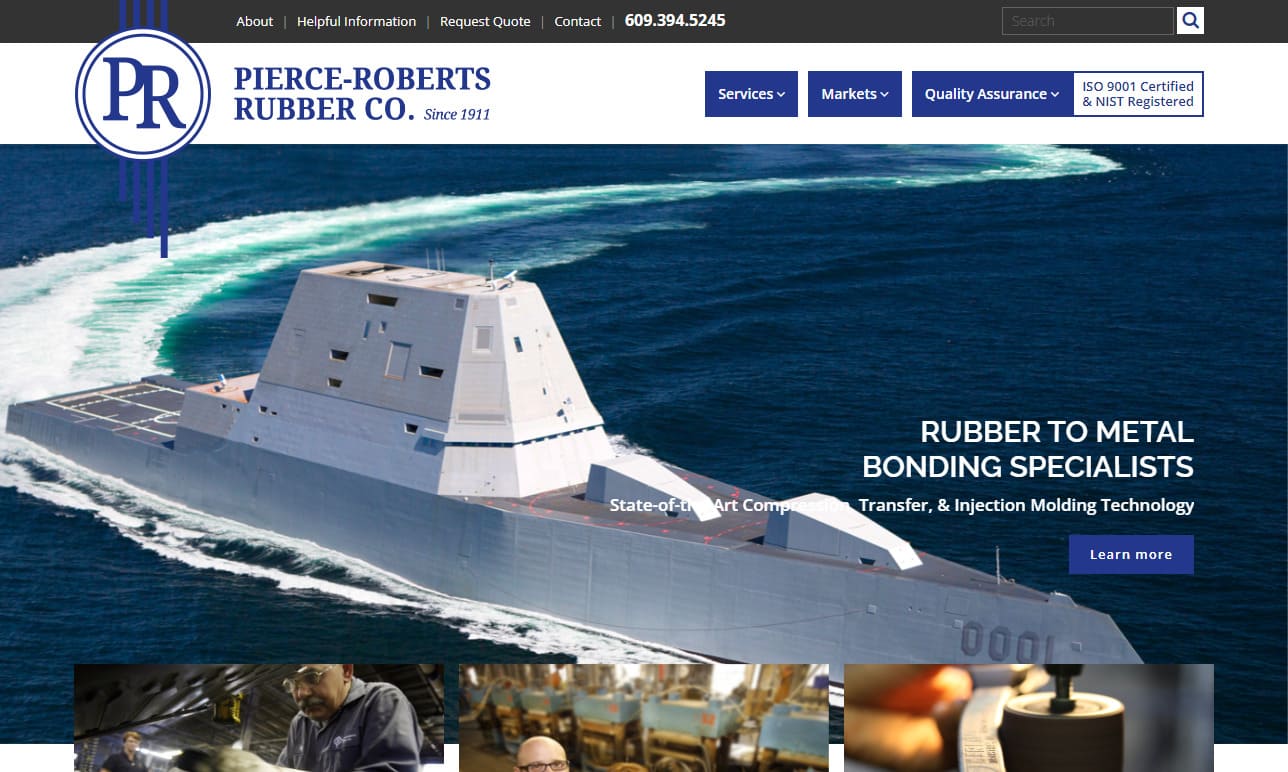

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

From molding products made of homogeneous rubber, to rubber bonded to metal as well as other various materials. Mason Rubber makes efficient use of state of the art technology to produce a quality product.

Our economical products are made from high-quality solutions that will last you for many years to come. We are a dependable manufacturer that will work with you every step of the way.

Since 1955, Jet Rubber Company, an Employee Owned Company, has been custom molding rubber and rubber-to-metal components for a variety of industries and applications.

More Rubber Bonded to Metal Manufacturers

Synthetic rubbers are used more often in rubber bonding applications because they may be altered in production to suit certain types of metals or adhesives, always with the goal of producing the strongest, most reliable bond.

The metal may also be any kind of metal, although it is usually steel or aluminum. Steel and steel alloys such as stainless steel, have been the most common of bonded metal products for many years because of its durability and intense resistance to corrosion.

However, in recent years the same qualities have been exhibited in aluminum with the additional attributes of low cost and light weight, making aluminum bonding just as popular, if not more so. The bonding agent varies depending on the type of rubber and the type of metal being bonded. Industrial adhesives have been a staple choice, although water-based adhesives are gaining numbers because of their environmentally friendly aspects.

Although the rubber, the metallic element and the adhesive may vary from application to application, depending on the physical characteristics desired by the buyer, the process is pretty standard across the board. The metal substrate is sprayed with the bonding agent and then laid in a mold, upon which is then poured uncured rubber.

Keeping the metal substrate steady within the mold is one of the most difficult and crucial aspects of the process, since the part must be fully coated to come out correct. When the hot, nearly melted rubber cools, the rubber bonded to metal product is finished and ready to go. The products produced by this process are used in many different manufacturing applications, specifically for the isolation of vibration.

The automotive industry in particular uses many rubber bonded parts, although many other industries utilize them as well. To name a few, industrial manufacturing companies, electronic companies and farm tool companies all utilize the gears and bearings produced from bonded rubber and metal products. The medical industry requires the physical characteristics of silicon bonded materials in particular for surgical instruments and other medical supplies.

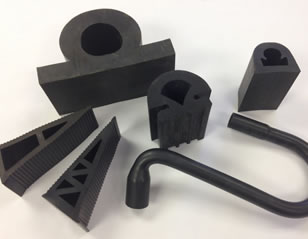

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

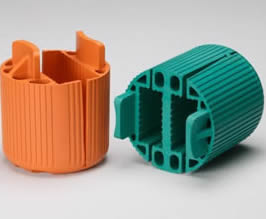

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services