Rubber bonding is joining two pieces of rubber or rubber and another substance, such as metal, wood, or plastic. One can either use hot rubber bonding or cold rubber bonding. Although both have benefits, a hot rubber bond is typically stronger than a cold bond. However, hot rubber bonding is a more expensive procedure requiring more setup and labor, raising a product’s cost. Choosing the right procedure depends on the application of the final product. Read More…

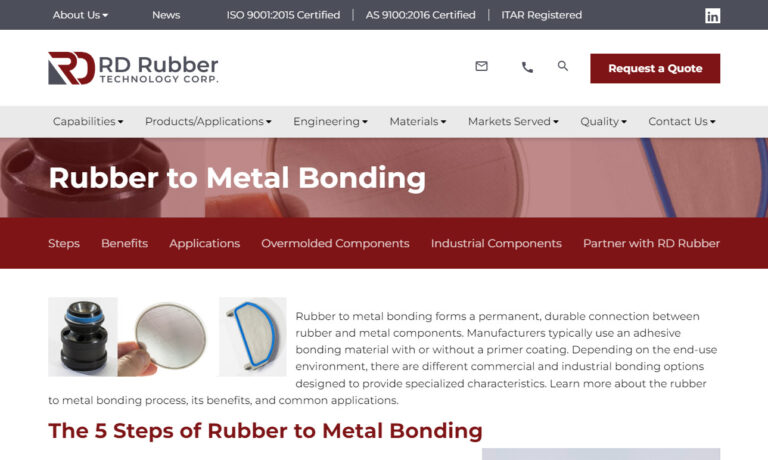

RD Rubber Technology is an ISO 9001:2015 certified company that is highly responsive and flexible to customer needs. We can take care of design, development, and prototyping as well as short run, long run, and high volume production. We offer compression, transfer, LIM, and rubber to metal bonding. We also do silicone to thermal plastic bonding.

Since 1984 we have been providing excellent high performance solution to our client’s toughest bonded metal to rubber issues. Our skilled teams of engineers and technicians will work closely with you in order to ensure that we are filling your exact requirements on the products that we provide. Allow us to show you the difference when you work with true experienced professionals. Visit our...

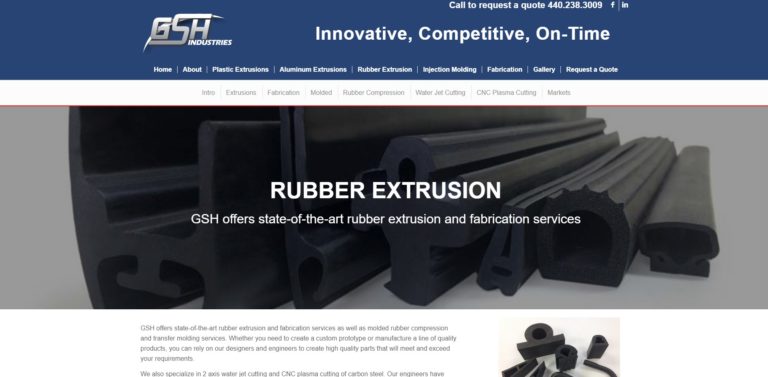

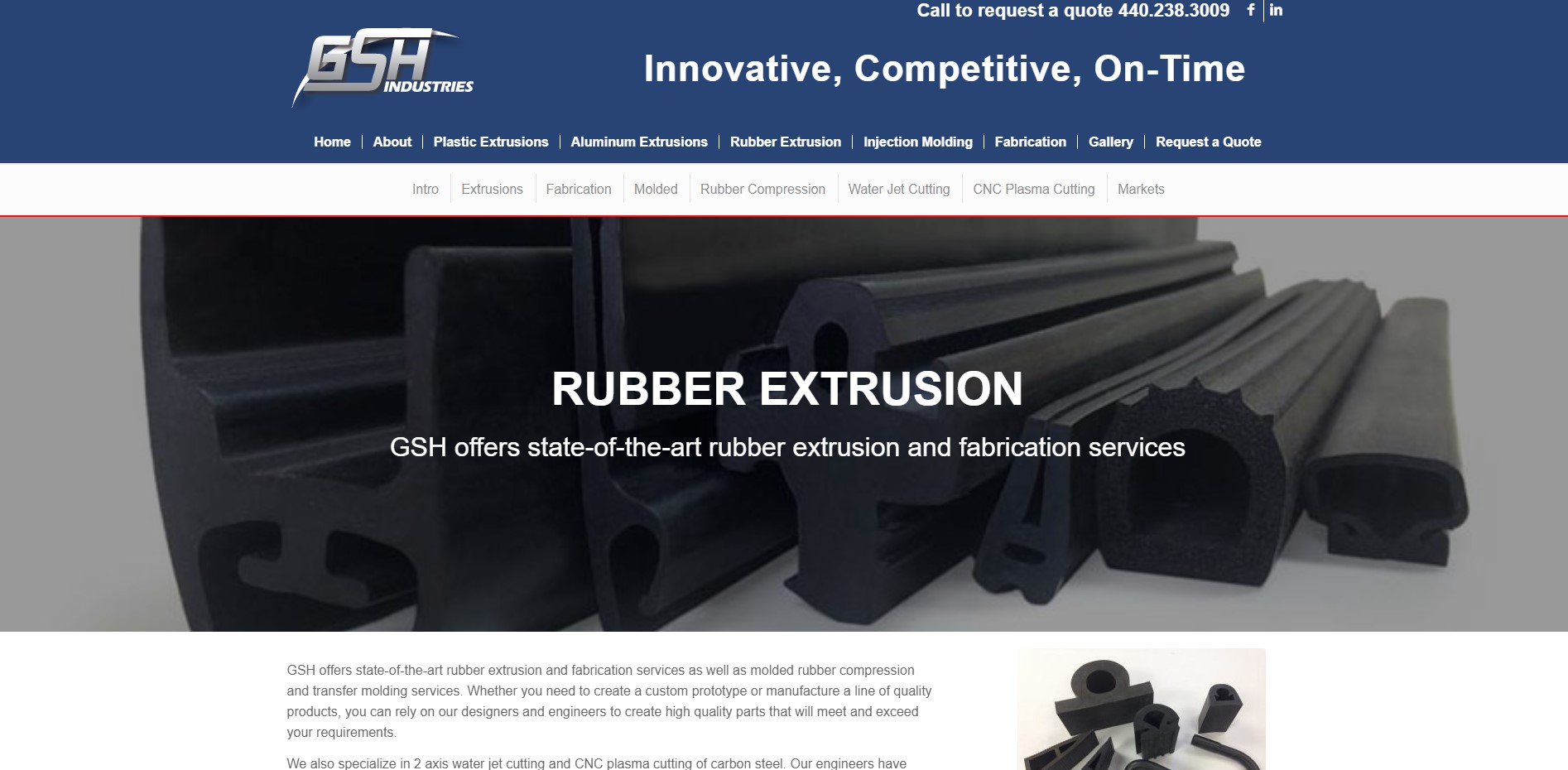

For over 25 years, GSH has provided top quality contract manufacturing services, and we strive to remain on the cutting edge of our industry.

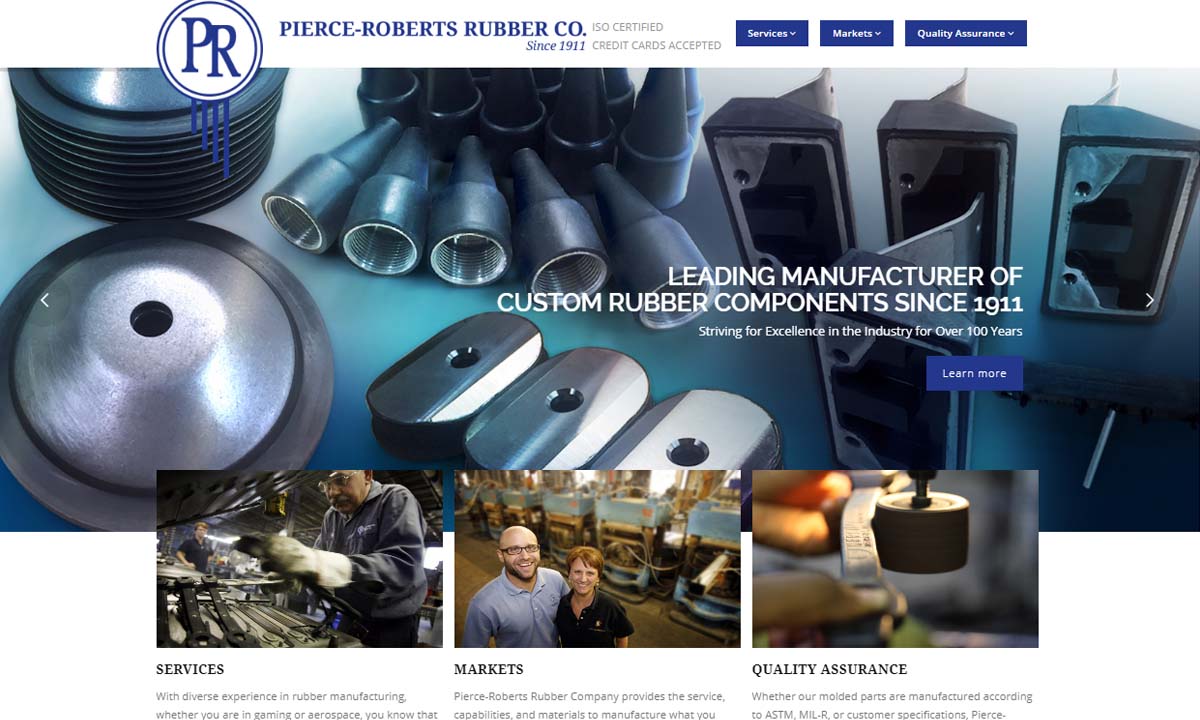

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

From molding products made of homogeneous rubber, to rubber bonded to metal as well as other various materials. Mason Rubber makes efficient use of state of the art technology to produce a quality product.

Our economical products are made from high-quality solutions that will last you for many years to come. We are a dependable manufacturer that will work with you every step of the way.

Since 1955, Jet Rubber Company, an Employee Owned Company, has been custom molding rubber and rubber-to-metal components for a variety of industries and applications.

More Rubber Bonding Manufacturers

What to Consider When Choosing an Adhesive for Rubber Bonding

Different kinds of rubber have different physical, chemical, thermal, and electrical properties. Manufacturers should consider this when choosing adhesive solutions. When natural or synthetic rubbers are bonded to each other, metals, plastics, ceramics, or glass, the requirements of the adhesive solutions will vary. Adhesives must be suited to the rubber material and the intended application. However, a large variety of adhesives, including many different kinds of rubber adhesives, are readily accessible and generally suitable for a strong bind.

The Properties of a Perfect Rubber Adhesive

Most rubber varieties work well with two-component adhesives and superglues. One can utilize one of these adhesives, for instance, if one desires to bond a rubber mat to wood.

Versatility

Many materials can already be combined using all-purpose glue accessible in the marketplace. Still, these joints are frequently less reliable than those created using a specialized rubber adhesive. Retail glue contains solvents. Hot melt adhesives may also work well for joining rubber to metal. In addition, these can be used to join various materials, like latex.

Adhesion

A good rubber adhesive should be flexible. Most rubber products, such as rubber hoses and shoe soles, are flexible; therefore, the adhesive must be strong enough to bend and flex without breaking or cracking.

Curing Time

Manufacturers should also consider an adhesive’s drying period. Some glue, such as super glue, dries very quickly, making it possible to swiftly determine whether the bond is strong and resilient. Unfortunately, some will set a little later than others.

Elasticity

The project one wishes to finish will also determine how stretchy the rubber glue needs. The sulfur level of rubber glue is important in terms of elasticity. Rubber glue becomes less elastic as its sulfur level rises.

The Different Types of Rubber Adhesives

Silicone Rubber Adhesives

Silicone-based glue can be the best choice if seeking a very elastic and flexible rubber adhesive. After curing, silicone rubber adhesives become extremely flexible and heat, moisture, and chemical resistant.

Structural Acrylic Rubber Adhesives

Epoxy glues work well for adhering rubber quickly after hardening. Two-part epoxy glues are the best options for rubber bonding. In addition, two-part epoxy adhesives have a longer shelf life than one-part glues.

Cyanoacrylate Rubber Adhesives

Cyanoacrylate rubber adhesives, called superglue, are appropriate for practically all rubber applications. Additionally, superglue is one of the most adaptable alternatives available, working well on various materials, including metal and plastic. Although moisture is needed for superglue adhesives to cure, the instantaneous bond is stiff and strong. However, it is not advised for rubber projects that need flexibility.

A Step-by-Step Guide for Gluing Rubber

Rubber bonding is a simple process that even novice artisans can complete.

Preparation

The ideal rubber adhesive should match the composition of the two materials to be bonded. The surface that needs to be bonded must be completely clean to ensure optimal adhesion. This includes any grease and oil build-up in addition to dust and debris. Sandpaper can provide a rough surface to give the rubber adhesive an extra grip. One can also use a primer to enhance outcomes.

Rubber Adhesive Application

Now that the adhesive has been evenly applied to one side, ensure the area is sufficiently aired. The rubber adhesive can be applied using a brush or a spatula. One must pay attention to the flash-off time if a solvent-based adhesive is used to attach the rubber. The manufacturer's instructions specify this. Fix the two surfaces that need to be bonded together by pressing them together once the flash-off time has passed.

Curing

The adhesive takes up to 24 hours to attain its maximum strength. The ambient temperature and humidity affect this period. In addition, the drying period of the rubber glue affects its suppleness. The bonded parts might undergo additional mechanical processing following the curing procedure.

Choosing the Proper Rubber Bonding Company

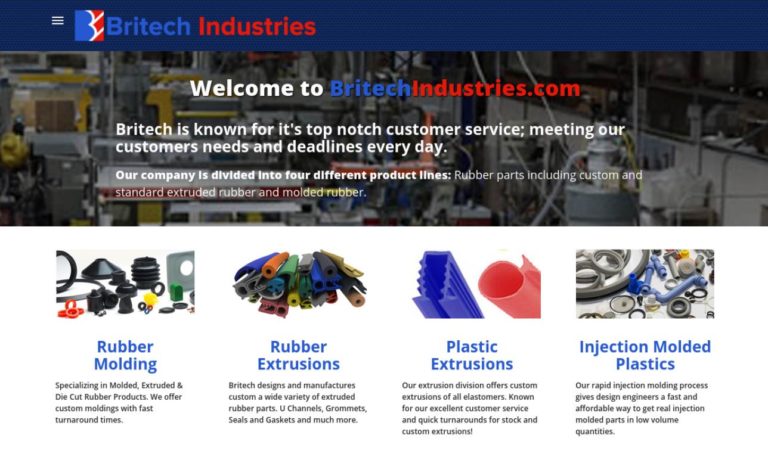

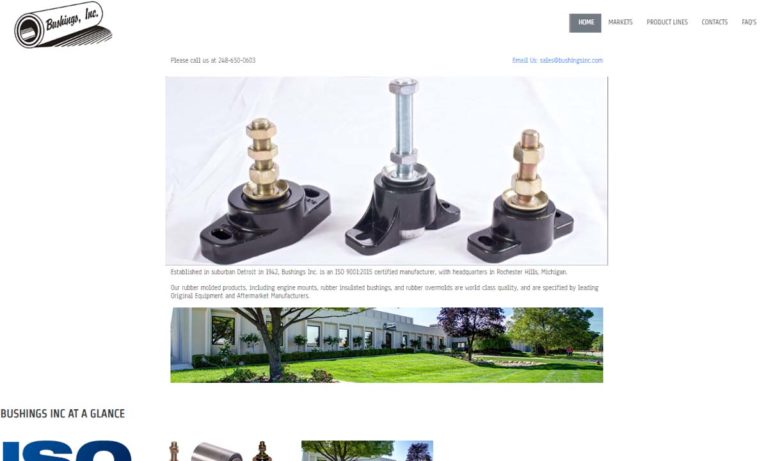

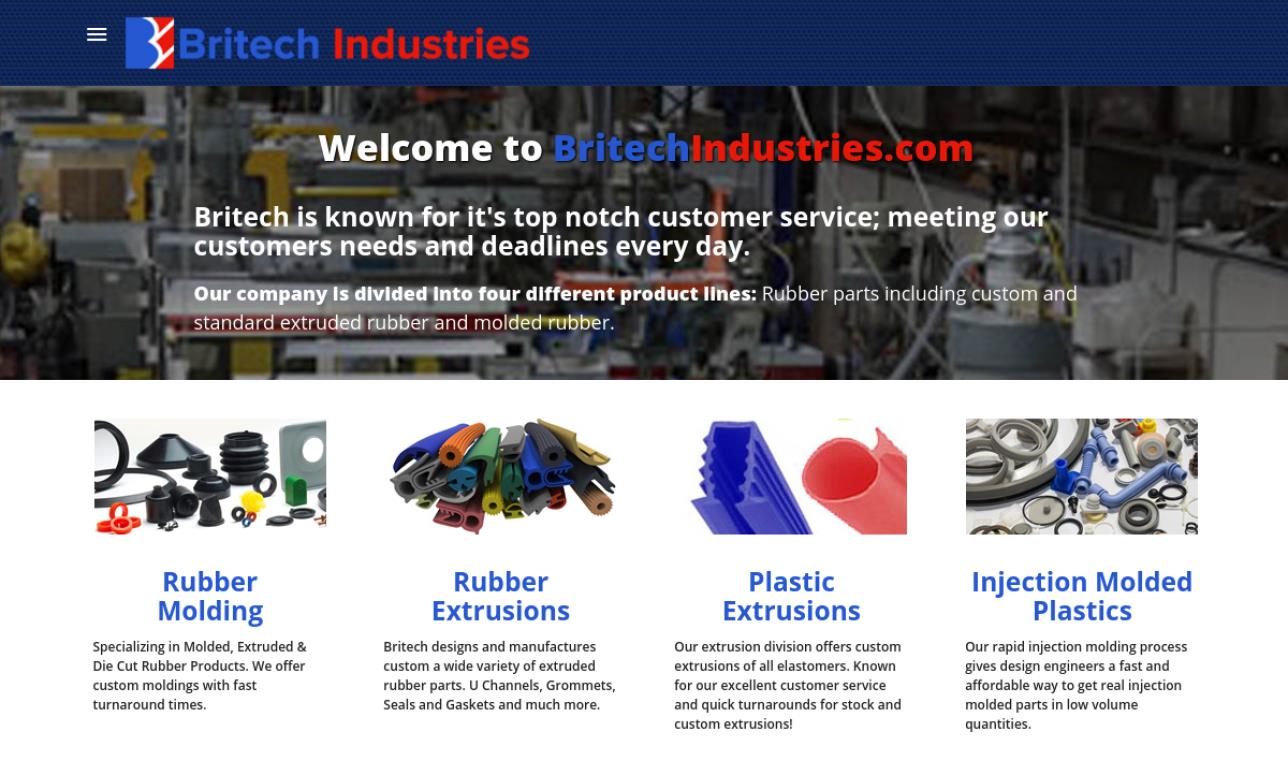

To make sure you have the most beneficial outcome when selecting a rubber bonding company, it is important to compare at least 4 to 5 companies using our rubber bonding directory. Each rubber bonding company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each rubber bonding company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple rubber bonding companies with the same quote.

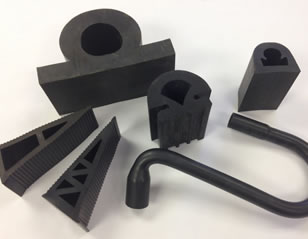

Rubber Extrusions

Rubber Extrusions Rubber Molding

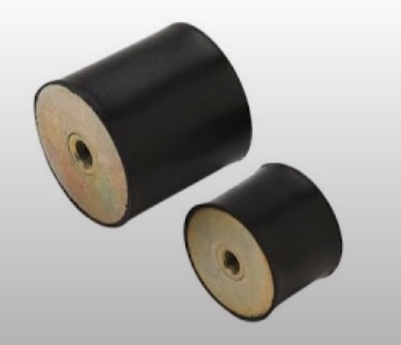

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

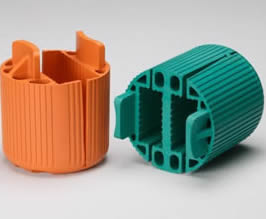

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services