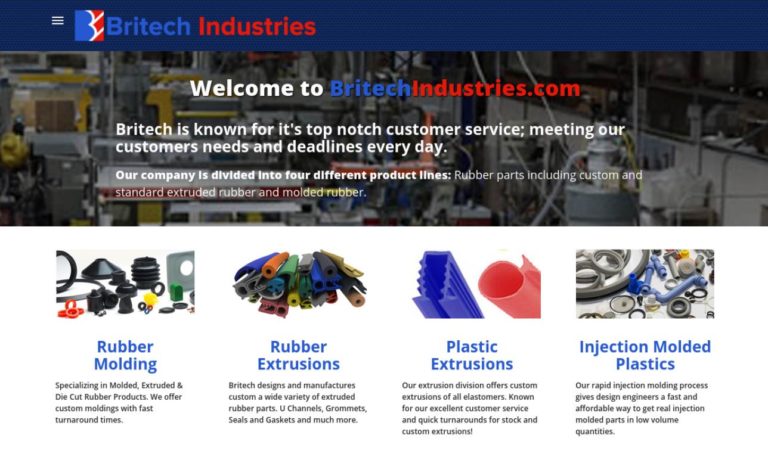

The rubber is at first uncured, then injected or poured into a mold containing the metal substrate. The substances making up the rubber material must not bleed rapidly to the surface of the uncured stock. Any type of rubber can be bonded to another harder material, including natural, pure rubber, neoprene, silicon, EPDM and nitrile. Each of these rubber compounds have unique benefits and qualities, including temperature resistance, water resistance, durability, ability to withstand high psi, continuous wear and contact with oil or chemicals. Read More…

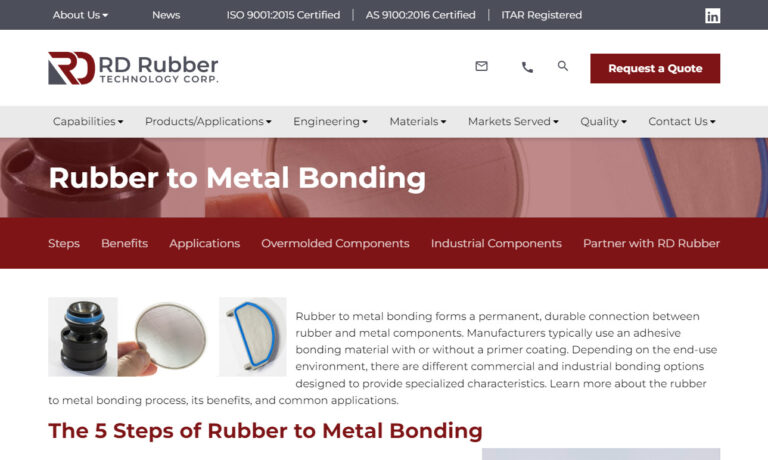

RD Rubber Technology is an ISO 9001:2015 certified company that is highly responsive and flexible to customer needs. We can take care of design, development, and prototyping as well as short run, long run, and high volume production. We offer compression, transfer, LIM, and rubber to metal bonding. We also do silicone to thermal plastic bonding.

Since 1984 we have been providing excellent high performance solution to our client’s toughest bonded metal to rubber issues. Our skilled teams of engineers and technicians will work closely with you in order to ensure that we are filling your exact requirements on the products that we provide. Allow us to show you the difference when you work with true experienced professionals. Visit our...

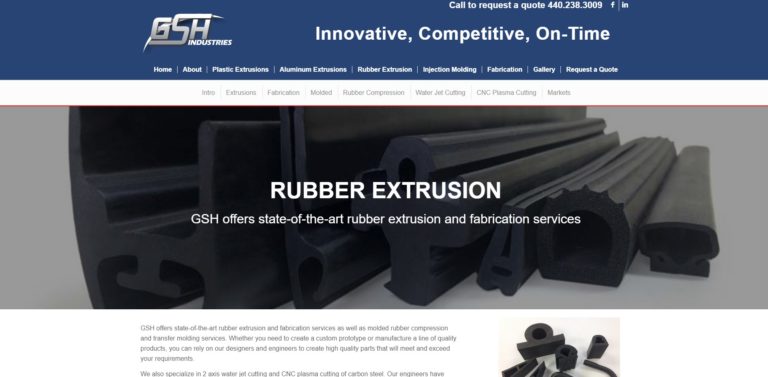

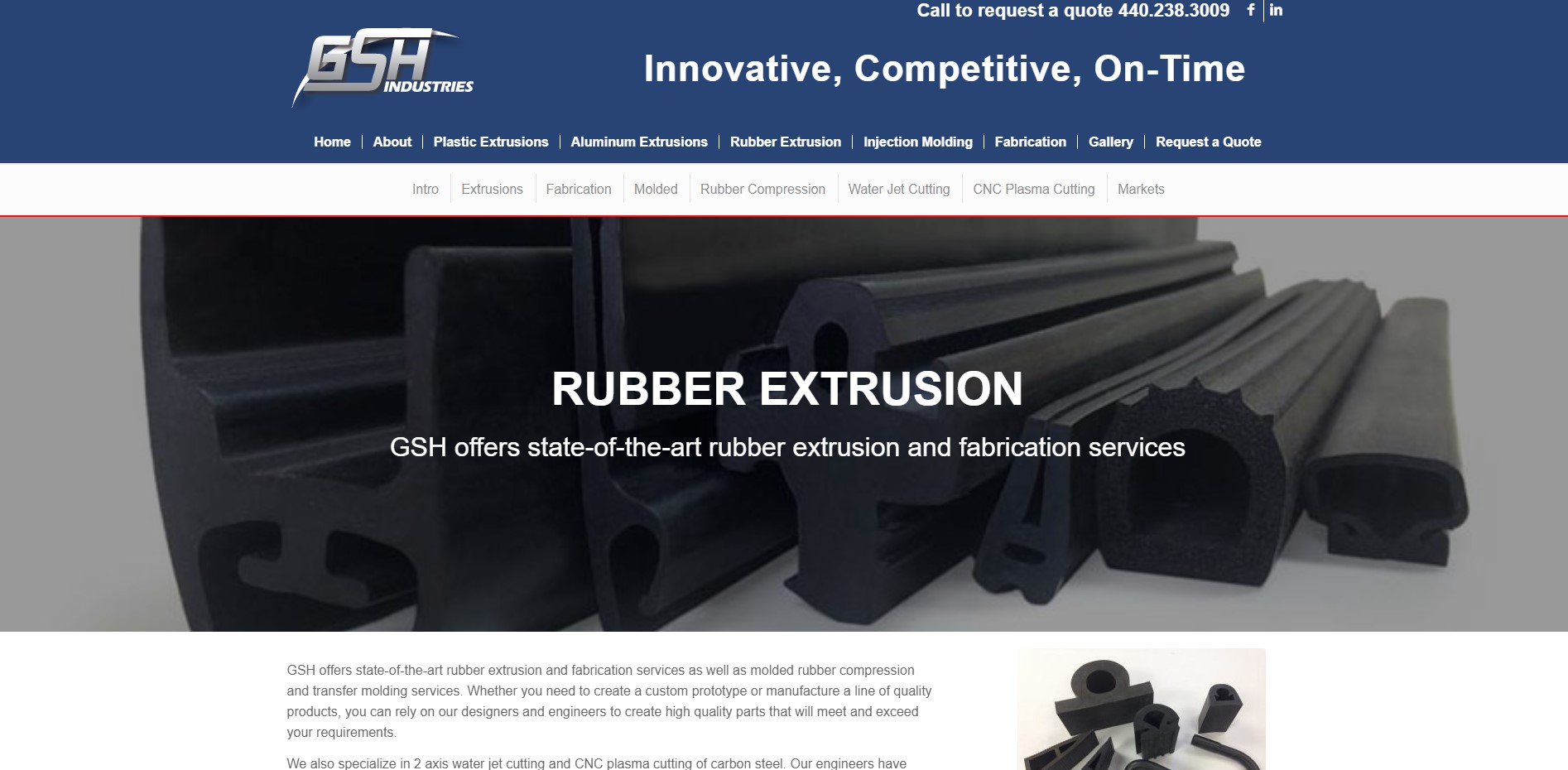

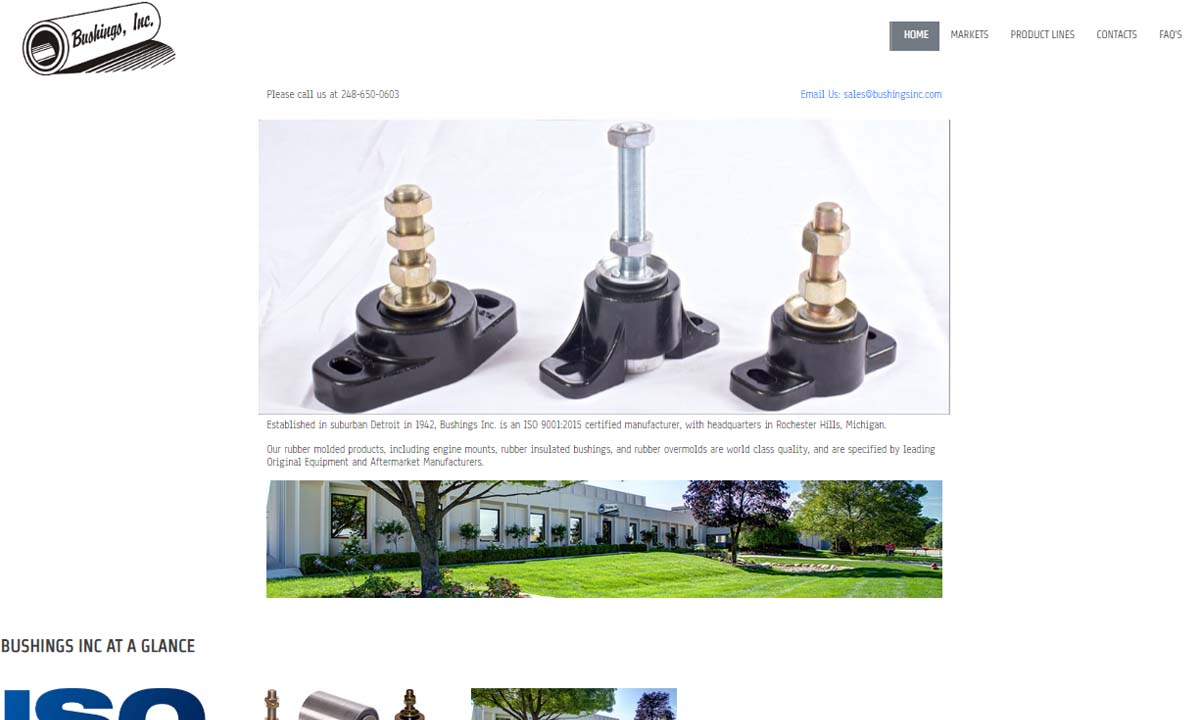

For over 25 years, GSH has provided top quality contract manufacturing services, and we strive to remain on the cutting edge of our industry.

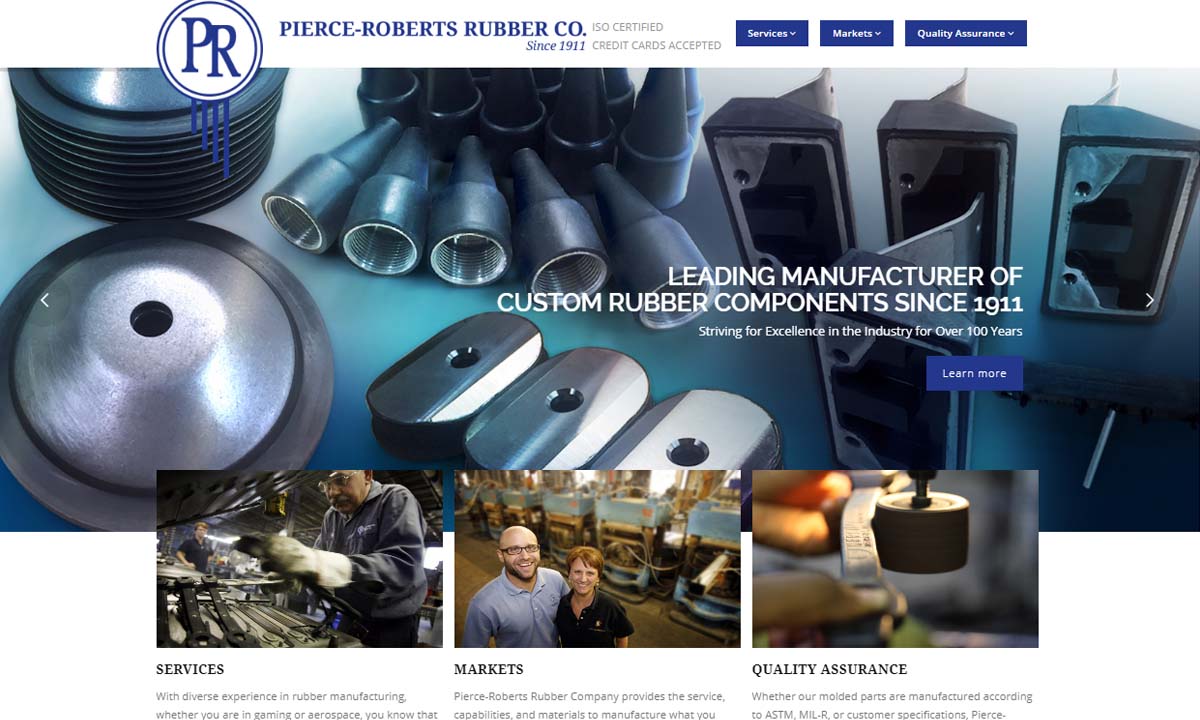

With more than a century of manufacturing experience, Pierce-Roberts Rubber Co. is your source for custom molded rubber products.

From molding products made of homogeneous rubber, to rubber bonded to metal as well as other various materials. Mason Rubber makes efficient use of state of the art technology to produce a quality product.

Our economical products are made from high-quality solutions that will last you for many years to come. We are a dependable manufacturer that will work with you every step of the way.

Since 1955, Jet Rubber Company, an Employee Owned Company, has been custom molding rubber and rubber-to-metal components for a variety of industries and applications.

More Bonded Rubber Manufacturers

With each specific rubber offering unique capabilities, many manufacturers of rubber bonded to metal procedures offer custom design options so that the customer may get exactly what they want. Rubber effectively forms a water and air tight seal with metal with the use of an adhesive coating between the two.

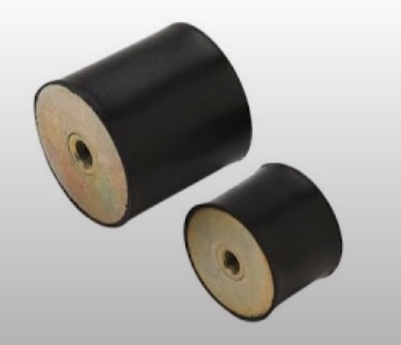

Types of adhesives that work well between metals and rubbers include industrial adhesives such as silicone and polyurethane. This forms many different products, usually for industrial rather than commercial use, including medical instruments, bearings, gears, plugs, washers, vibration dampeners, rubber lined tanks, building construction components, rubber-lined piping systems and many others.

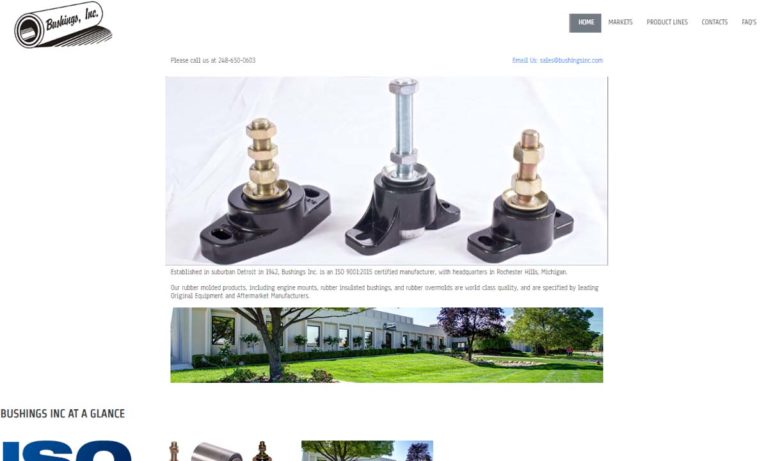

There are three main components within the rubber to metal bonding process: the metal substrate, the rubber material and the adhesive agents that bond the two together. The process of forming the bonded product is simple, but depending on the type of metal and rubber used, could take over an hour to complete.

The substrate must be thoroughly cleaned and degreased before the bonding can start. Then, it is coated with a primer and top coat of adhesives, either solvent or water based. Then the most important part of bonding, the molding process, takes place next. The rubber material is heated and injected or poured into the mold cavity that now contains the metal substrate.

Once the mold is filled and the metal component is positioned perfectly, the rubber is given a chance to cure and is then removed from the mold when dry. Sometimes plated inserts are added into the mold to enhance strength and durability of the part.

Bonded rubber and metal products are durable, long lasting and are bonded together to form an extremely strong seal. The bond is actually stronger than the elastomeric rubber itself, so if there is product failure, it lies in the rubber's inability to withstand pressure.

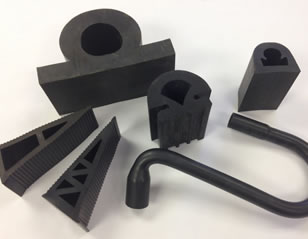

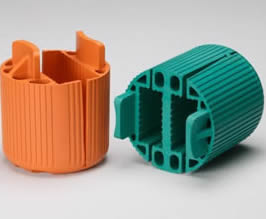

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services